Galvanized, Galvalume, Copper & More

Galvalume, Galvanized, Gand Copper Metal Roofing Fabrication & Installation

Alpine Sheet Metal Systems designs, fabricates, and installs any type of custom metal roofing system. From luxury copper roofing to galvanized metal roofing. Our metal specialists will assist you in discovering what type of metal is appropriate for your project design, architectural style, functionality and budget.

With more than 25 years of fabrication and installation experience, you can count on Alpine Sheet Metal Systems to fabricate and install your metal roof efficiently and according to manufacturer warranty guidelines. We fabricate and install top-rated, high-end metal roofing manufacturer materials. Our seasoned metal professionals will ensure you get the appropriate product suited to your needs. Call our metal roofing experts for more information on our custom metal roofing fabrication process and begin your metal roof project today.

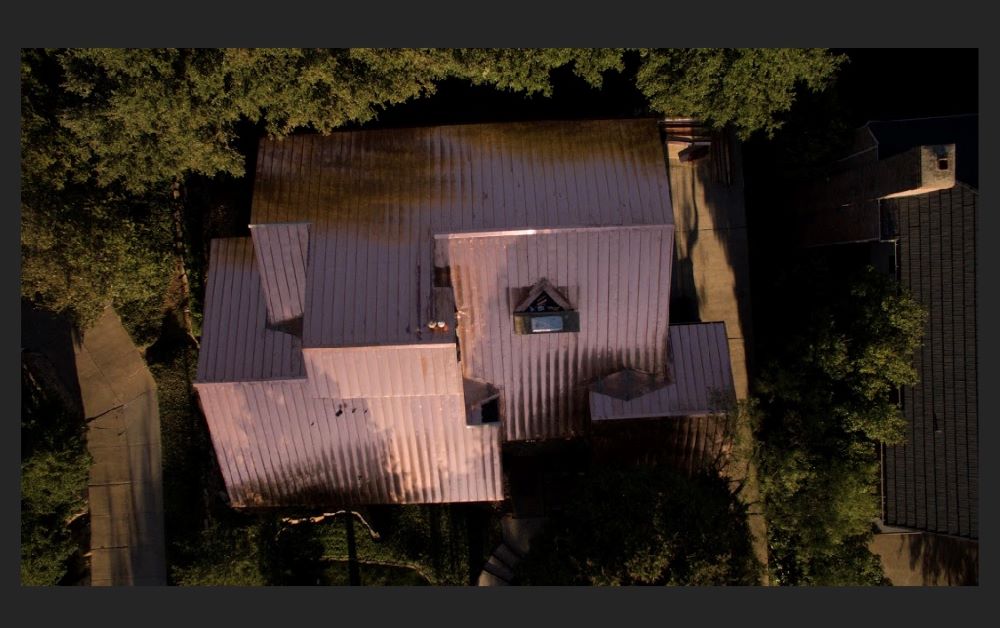

Copper Roofing Fabrication and Installation

Copper has been used as a roofing material for hundreds of years. Copper roofing is a highly desirable luxury roofing material and considered a status symbol by some. All copper metal evolves through a natural “patina” process due to environmental exposure. This patina process results in a variety of copper, green, bronze, red, and gold highlights. Copper is a strong metal, resistant to water damage, and highly sought after by architects, designers, and developers.

Copper is often used for roofing panels, shingles, architectural panels, drainage pipes, collector heads, rain gutters, and architectural accents. Properly maintained copper roofs will last the lifetime of the structure.

A copper roofing system is a wise investment as it will indefinitely hold its value.

Alpine Sheet Metal System’s metal specialists have decades of experience in custom fabricating and installing copper roofs, drainage solutions, rain gutters, shingles, panels, flashings, chimney caps, and architectural accents. We can hand-replicate any historical copper roof, shingles, and exterior envelope.

- Contemporary

- Classic

- Victorian

- Gothic

- Georgian

- Craftsman

- Mediterranian

- Mid-Century

- Spanish

- Roman

- Greek Revival

- French

- And Many More

Galvanized Steel Roofing Fabrication and Installation

Alpine Sheet Metal Systems has been roofing North Texas commercial and residential structures with galvanized steel roofing systems for over 25 years. Galvanized steel is iron or steel coated in a zinc alloy. This coating process is “hot-dip galvanizing”, achieved by submerging the steel or iron in a molten bath of hot zinc. Similar to electroplating, this zinc coating prevents rust and corrosion.

Galvanized steel is a popular metal roofing choice due to its ability to hold paint well, minor scratch resistance, rust resistance, availability, and affordability. The more zinc coatings applied, the thicker the gauge, resulting in a longer life span of the galvanized steel roofing system.

Galvanized Steel Roofing Fabrication and Installation

- Galvanized steel is a low-maintenance metal known for durability.

- Readily Available

- Cost-Effective

- Lightweight – easy to use – transports easily – cuts easily as well.

- Corrugated Galvanized Steel Panels will not rot, mildew or warp.

- Insect (termite) resistant

- Available in a wide variety of colors.

- Can be fabricated in a variety of styles

- Fire-resistant – This could lead to lower insurance premiums.

- 100% Recyclable

Galvalume Steel Fabrication and Installation

Galvalume is steel metal roofing coated with a metal alloy consisting of 45% zinc and 55% aluminum. The combination of zinc and aluminum enhances the positive and negative effects of aluminum. This process creates a corrosion and heat-resistant barrier. Galvalume will resist rust, elements, and fire while providing a sturdy and protective covering.

The aluminum provides corrosion protection, and zinc provides durability. This combination makes Galvalume a practical choice for a metal roofing system or panel. The metal coating protects the steel from rusting and perforating as well.

Galvalume has a matte finish, often lending itself for use on commercial, agricultural and residential projects. Some consider Galvalume industrial/modern or rustic in appearance, and it is often used in contemporary offices, condominiums and restaurants.

Galvalume typically lasts much longer than galvanized steel. Galvalume often comes with a 25-year warranty; this cannot be provided with Galvanized steel.

Advantages of Galvalume Steel

- Galvalume steel is a low-maintenance metal known for high-performance durability.

- Readily Available

- Cost-Effective

- Performs well in high temperatures

- Performs well in moist marine environments

- Insect (termite) resistant

- Available in a wide variety of colors

- Can be fabricated in a variety of styles

- Fire-resistant – This could lead to lower insurance premiums.

- 35% Recyclable

Steel Sheet Metal Roofing Fabrication

Alpine Sheet Metal Systems has been fabricating and installing commercial & residential steel roofing systems for more than 25 years. Many people associate steel roofing with warehouses, factories, and industrial buildings. Steel is now used in a multitude of structures and architectural designs. Stainless steel roofing was introduced in 1924 as a staple in Art Deco architectural design, thus qualifying stainless steel as a historical roofing material. The iconic Chrysler building in New York City is a perfect example of stainless steel building. Steel roofing is extremely durable. Many historical structures with steel roofs and exterior envelopes remain in place today. Alpine Sheet Metal Systems‘ steel technicians have over 25 years of experience fabricating, installing, replacing, and restoring new & historical stainless steel roofing and exterior envelope systems.

- Durability: One of the primary benefits of stainless steel roofing is its ability to withstand harsh weather and corrosion. Stainless steel roofs excel in all weather conditions and can last the lifetime of a structure.

- Few Repairs: Stainless steel roofing systems rarely require repairs. A professionally installed and maintained stainless steel roof will require very few repairs over its lifetime. If your stainless steel roofing should require repair, Alpine Sheet Metal Systems’ metal experts are prepared to help you.

- Environmental Friendliness: Most stainless steel in use today is made from recycled and recyclable materials. A stainless steel roof can be salvaged and repurposed at the end of its lifespan. Stainless steel roofing is highly reflective which reduces heat from building up in your structure, resulting in lower energy costs in the brutal North Texas summer heat.

- Versatility: Stainless steel is highly malleable and easy to work with, making it possible for stainless steel roofing specialists to create innovative moldings, cornices, and other beautiful architectural design elements. Rare and intricate architectural details can easily be fabricated out of stainless steel.

- Affordability: Stainless steel is a fraction of the expense of copper while offering many of the same characteristics. As a result, it is a great choice for ornamental metal roofs and architectural details.

- Safety: Stainless steel roofing systems are safe roofing choices due to their severe weather and fire resistance. Some stainless steel roofs have withstood 180mph wind gusts.

- Flexibility: Stainless steel is relatively lightweight, which means it can be installed on top of an existing roof with little modification. This greatly reduces the time and costs associated with stainless steel roof fabrication and installation.